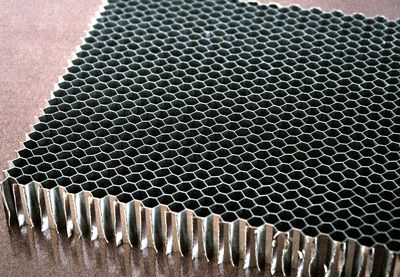

Aluminum honeycomb core

Description: aluminum honeycomb core is made of multilayer foil bonded, laminated and then pull stretched into honeycomb shapes. As a family of cellular "aristocracy", aluminum honeycomb has a very good performance, high strength, high temperature resistance, corrosion resistance, is used on the aviation, aerospace, ideal material for high-speed ships, high-speed trains and so on. In the construction industry it is used preferentially on the large size wall and indoor decoration materials with the flame retardant of demanding. Our company produces aluminum honeycomb core made of high quality aluminum foil (thickness 0.03mm~0.25mm) and high strength adhesive processing, and advanced technology, strict production control, honeycomb has high bond strength and stable performance.

|

鋁蜂窩芯主要規(guī)格參數(shù)

|

邊長

|

孔距

|

鋁箔厚度

|

公稱密度Kg/M3

|

壓縮穩(wěn)定性(常溫)

|

可展開尺寸(長×寬)

|

|

強(qiáng)度MPa

|

模量MPa

|

|

1.5 mm

|

2.6 mm

|

0.03 mm

|

82.9

|

4.2

|

926

|

1200×2400 mm

|

|

2 mm

|

3.4 mm

|

0.04 mm

|

82.8

|

3.1

|

713

|

1200×2400 mm

|

|

2.5 mm

|

4.3 mm

|

0.04 mm

|

66.4

|

2.7

|

561

|

1200×2400 mm

|

|

3 mm

|

5.2 mm

|

0.04 mm

|

55.3

|

1.6

|

324

|

1200×2400 mm

|

|

4 mm

|

6.9 mm

|

0.05 mm

|

51.8

|

1.65

|

337

|

1600×3200 mm

|

|

5 mm

|

8.7 mm

|

0.05 mm

|

41.5

|

0.95

|

292

|

1600×3200 mm

|

|

6 mm

|

10.4 mm

|

0.06 mm

|

41.4

|

0.88

|

225

|

1600×4600 mm

|

|

8 mm

|

13.9 mm

|

0.07 mm

|

36.4

|

0.78

|

178

|

1600×4600 mm

|

|

10 mm

|

17.3 mm

|

0.07 mm

|

29

|

0.65

|

149

|

1600×4600 mm

|

|

12 mm

|

20.8 mm

|

0.08 mm

|

27.6

|

0.62

|

136

|

1600×7500 mm

|

|

15 mm

|

26 mm

|

0.08 mm

|

22.1

|

0.53

|

112

|

1600×7500 mm

|

|

20 mm

|

34.6 mm

|

0.08 mm

|

16.6

|

0.45

|

95

|

1600×9000 mm

|

鋁蜂窩芯主要技術(shù)指標(biāo)

|

項(xiàng)目

|

單位

|

實(shí)驗(yàn)結(jié)果

|

|

節(jié)點(diǎn)強(qiáng)度

|

Kg/cm2

|

1.5~1.7

|

|

板—芯90°剝離

|

? |

4.8~5.6

|

|

縱向彎曲強(qiáng)度

|

? |

8.6~11.6

|

|

橫向彎曲強(qiáng)度

|

Kg/cm2

|

7.4~9.3

|

|

抗壓強(qiáng)度

|

0.04/4

|

Kg/cm2

|

10~12

|

|

0.04/5

|

Kg/cm2

|

6~7.5

|

|

0.04/6

|

Kg/cm2

|

3~4.2

|

|

0.04/3

|

Kg/cm2

|

15~18

|

|

熱膨脹系數(shù)

|

/℃

|

23×10-6

|

|

熱傳導(dǎo)率

|

W/M℃

|

1.7

|

- 燃燒性

|

不燃

|

鋁蜂窩芯的性能

|

芯規(guī)格

|

密度kg/cm3

|

壓縮穩(wěn)定性

|

板剪切

|

|

強(qiáng)度Mpa

|

模量Mpa

|

L方向強(qiáng)度Mpa

|

L方向模量Mpa

|

W方向強(qiáng)度Mpa

|

W方向模量Mpa

|

|

1″

|

22.4

|

0.53

|

112

|

0.39

|

98

|

0.23

|

49

|

|

3/4″

|

28.5

|

0.77

|

168

|

0.67

|

112

|

0.39

|

56

|

|

3/8″

|

53.6

|

2.28

|

644

|

1.47

|

280

|

0.91

|

140

|

|

1/4″

|

81.8

|

4.34

|

1036

|

2.42

|

441

|

1.51

|

217

|

|

3/16″

|

117.4

|

5.25

|

1120

|

3.15

|

525

|

1.82

|

280

|

|

|